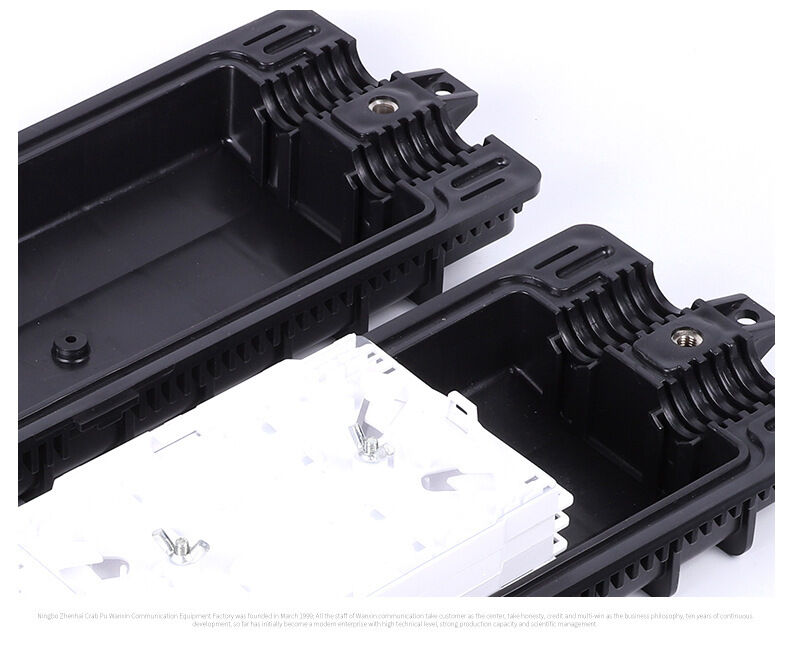

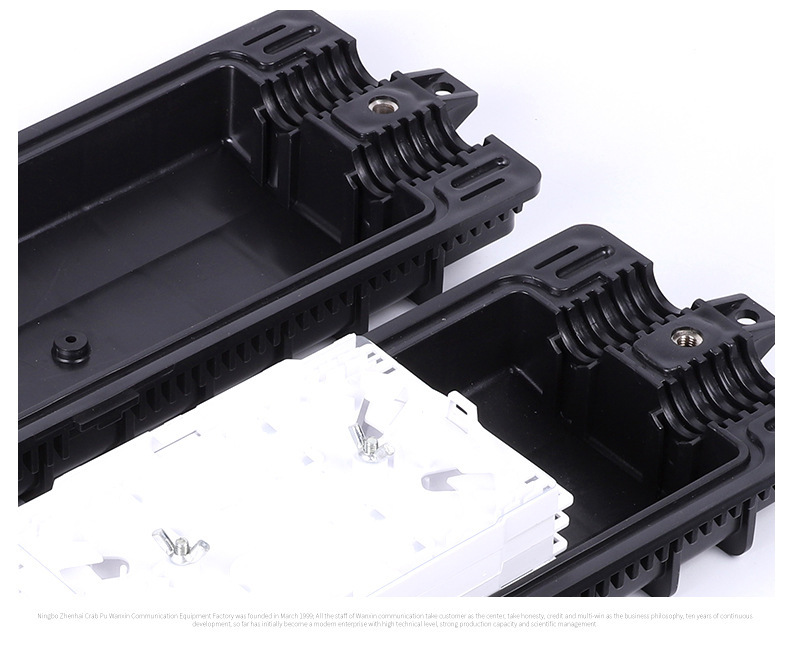

48 Cores Inline Type Fiber Optic Splice Closure 2 In 2 Out Waterproof

An inline fiber optic closure is a protective housing used to splice, branch, and store fiber optic cables along a run of a cable route. Unlike a dome or wall-mounted closure, it is designed to be installed in-line (directly on the cable) in aerial, underground, or buried applications, creating a sealed, durable, and re-enterable junction point.

Specification:

| Advantages |

Disadvantages |

| Environmental Protection: Excellent seal against moisture/contaminants. |

Installation Skill: Requires trained technicians for proper sealing. |

| Mechanical Protection: Shields splices from crush, impact, and strain. |

Size: Can be bulky, especially for high fiber counts. |

| Flexibility: Re-enterable for network modifications. |

Cost: Higher initial cost than simple mechanical sleeves (but justified for permanent installations). |

| Organization: Internal trays keep fibers managed and identifiable. |

Aerial Wind Load: Adds a point of wind load on the aerial span. |

Types:

1.1 By Installation:

Aerial: Mounted on a support strand between poles. Lightweight, UV-resistant, with strong hanging brackets.

Underground/Buried: Installed in manholes, handholes, or directly buried. Have robust, corrosion-resistant shells and often a cylindrical "pill" shape to withstand backfill pressure and moisture.

Duct: Installed within a conduit or duct run.

1.2 By Cable Entry/Exit:

Throughput (Straight-Through): The most common. Cable enters one end and exits the other, maintaining the linear path. Used for point-to- point splicing.

Branching (Tap): One or more cables enter, and multiple smaller cables branch out. Used for network distribution or splitting.

Butt Splicing: Two cables come in from opposite ends and are spliced together internally.

Applications:

2.1 Long-Haul & Trunk Networks: Splicing together cables over long distances (e.g., between cities).

2.2 Fiber-to-the-Home (FTTH) Networks: Creating distribution points where a feeder cable is branched into multiple drop cables.

2.3 Network Repair & Restoration: Quickly restoring a severed cable by splicing in a new section.

2.4 Cable Segment Joining: Connecting manufacturing-length cable reels during initial deployment.

2.5 Transition Points: Changing cable types (e.g., from aerial to buried) or connecting armored to non-armored cable.

How to Select the Right Inline Closure:

3.1 Environment: Aerial, buried, underwater? Determines the IP (Ingress Protection) rating (e.g., IP68 for submersible) and material strength.

3.2 Cable Count & Fiber Count: Must accommodate the number of cables and total fiber strands (e.g., 2 cables x 144 fibers each).

3.3 Re-enterability: Do you need to add fibers or reconfigure later? Most are designed for multiple re-entries.

3.4 Sealing Method: Heat-shrink (very reliable but needs a torch), gel-seal (cleaner, tool-less), or mechanical compression.

3.5 Size & Port Configuration: Ensure it has enough ports of the correct diameter for your cables.

3.6 Standards Compliance: Should meet relevant industry standards (e.g., Telcordia GR-771, ICEA).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!